PRODUCT INFO

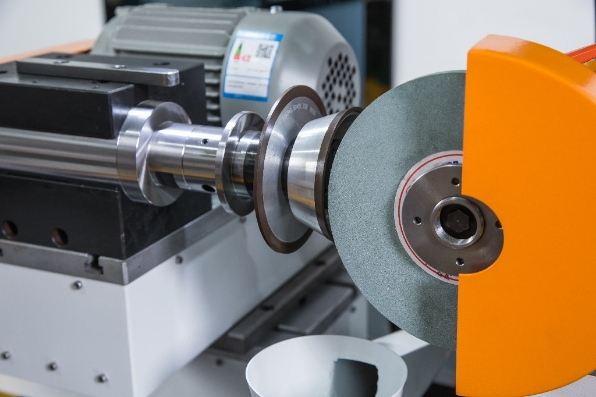

In modern manufacturing, precise grinding results are of critical importance. To ensure this level of precision consistently, regular maintenance and conditioning of your grinding wheels is essential. This is where our state-of-the-art grinding wheel dressing machines come into play.

Why is dressing grinding wheels so important?

Grinding wheels gradually lose their form and sharpness due to normal wear during the grinding process. Dressing is a necessary step to restore the wheel’s original geometry and performance. A precisely dressed grinding wheel not only ensures consistently high surface quality of your workpieces but also extends the service life of the grinding wheel itself.

Service and Support

Our commitment does not end with the sale. We offer comprehensive support and maintenance services to ensure that your grinding wheel dressing machine always remains in optimal condition. Our experts are available at any time to assist you with questions or concerns.

Our Grinding Wheel Dressing Machines – Your Advantages at a Glance

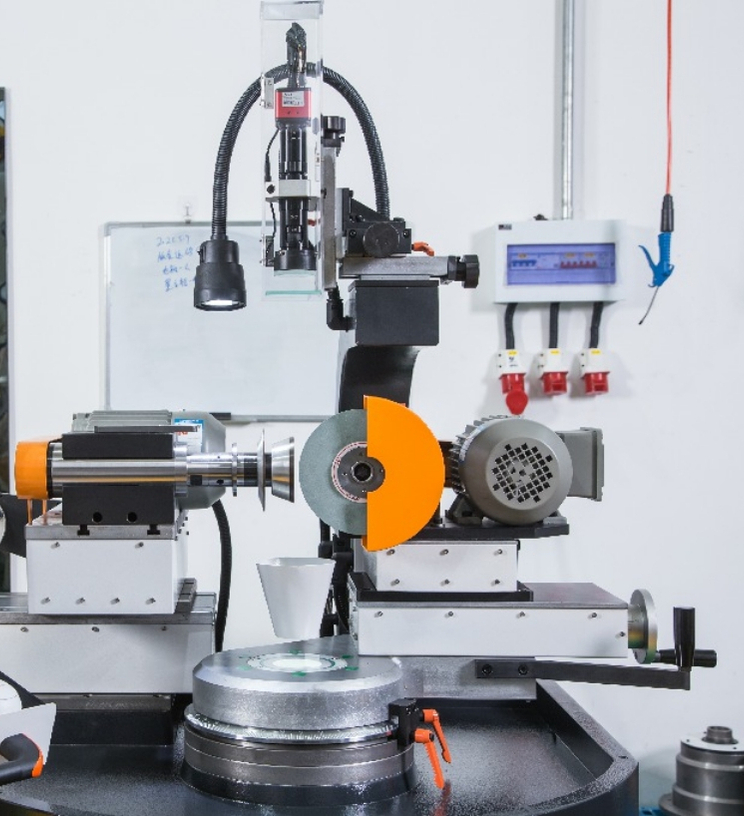

- Maximum Precision: Our dressing machines are designed to correct even the smallest deviations in grinding wheel geometry. This guarantees maximum accuracy in every grinding process.

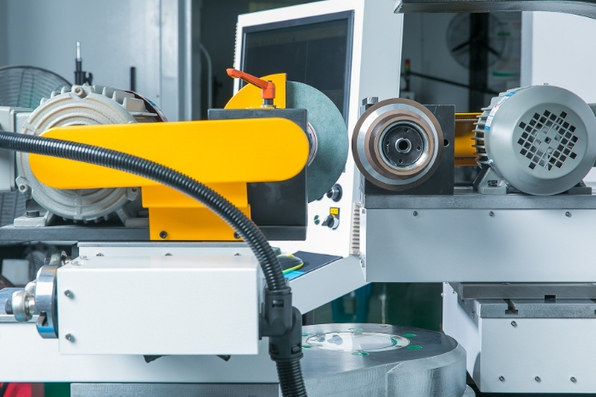

- User-Friendly Operation: With an intuitive user interface, our machines make the dressing process significantly easier. Even less experienced operators can use the machine quickly and efficiently.

- Robust Construction: Thanks to our cast-iron machine bed, the machine is extremely robust and designed with a simple structure. No unnecessary control electronics are installed. Simple and maintenance-friendly machine design is particularly important to us.

- Versatility: Our dressing machines are suitable for a wide range of grinding wheel types and sizes, making them a flexible solution for various manufacturing requirements.

GWDress dressing machine for grinding wheels

Technical data GWDress-250 Smartline

General

| Adapter/connectors | HSK 50 or customer request |

| max. grinding wheel diameter | ø 250 mm (up to ø 650mm possible) |

| max. dressing wheel diameter | ø 300 mm |

| Grinding wheel speed | 0-1500 rpm (stepless adjustable) |

| Dressing wheel speed | 0-2800 rpm (stepless adjustable) |

Movement range of axes

| max. travel path left/right | 135 mm |

| max. travel path back/forward | 135 mm |

Dressing

| Oscillation speed | 0-50 rpm |

| Swing length dressing wheel | 0-50 mm |

| Optical scale device (X, Y and rotary axis) | 0,001 mm |

Machine data

| Electrical connection | 380 V or other on request |

| Total power | 1,5 kW |

| Dimensions | ca. L 1200 x W 1200 x H 1900 mm |

| Weight incl. cast iron machine bed | 1.400 kg |

Software

| GWDress Studio Software | Open Source Software |

| DXF-Import | possible |

| Draw shapes in software | possible |

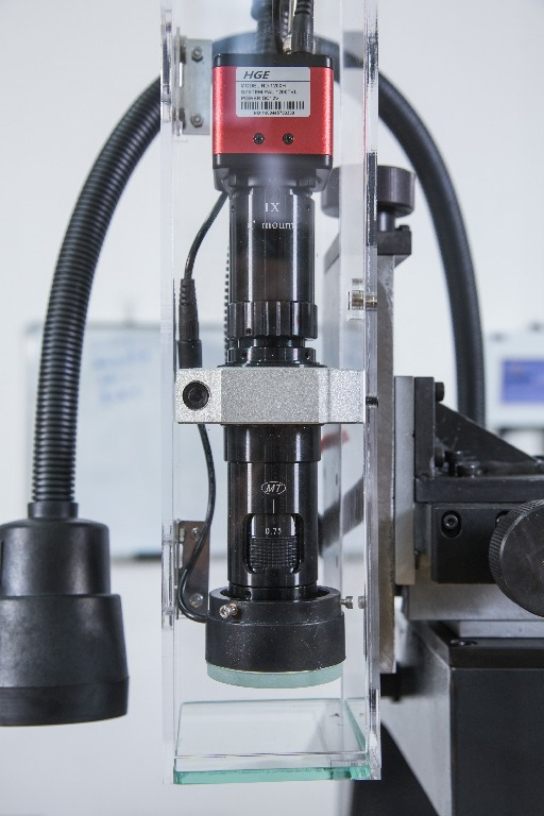

| Camera optics and magnification | included |

| 23" Monitor | included |

| 2-axis-control | included |

Further facts

| Radius dressing | possible |

| Dressing wheel packs | possible |

| Enclosure | included |

Technical data GWDress-250

General

| Adapter/connectors | HSK 50 or customer request |

| max. grinding wheel diameter | ø 250 mm (up to ø 650mm possible) |

| max. dressing wheel diameter | ø 300 mm |

| Grinding wheel speed | 0-1500 rpm (stepless adjustable) |

| Dressing wheel speed | 0-2800 rpm (stepless adjustable) |

Movement range of axes

| max. travel path left/right | 135 mm |

| max. travel path back/forward | 135 mm |

Dressing

| Oscillation speed | 0-50 rpm |

| Swing length dressing wheel | 0-50 mm |

| Optical scale device (X, Y and rotary axis) | 0,001 mm |

Machine data

| Electrical connection | 380 V or other on request |

| Total power | 1,5 kW |

| Dimensions | ca. L 1200 x W 1200 x H 1900 mm |

| Weight incl. cast iron machine bed | 1.400 kg |

Software

| GWDress Studio Software | Open Source Software |

| DXF-Import | possible |

| Draw shapes in software | possible |

| Camera optics and magnification | included |

| 23" Monitor | included |

Further facts

| Radius dressing | possible |

| Dressing wheel packs | possible |

Technical data GWDress-250 with enclosure

General

| Adapter/connectors | HSK 50 or customer request |

| max. grinding wheel diameter | ø 250 mm (up to ø 650mm possible) |

| max. dressing wheel diameter | ø 300 mm |

| Grinding wheel speed | 0-1500 rpm (stepless adjustable) |

| Dressing wheel speed | 0-2800 rpm (stepless adjustable) |

Movement range of axes

| max. travel path left/right | 135 mm |

| max. travel path back/forward | 135 mm |

Dressing

| Oscillation speed | 0-50 rpm |

| Swing length dressing wheel | 0-50 mm |

| Optical scale device (X, Y and rotary axis) | 0,001 mm |

Machine data

| Electrical connection | 380 V or other on request |

| Total power | 1,5 kW |

| Dimensions | ca. L 1200 x W 1200 x H 1900 mm |

| Weight incl. cast iron machine bed | 1.400 kg |

Software

| GWDress Studio Software | Open Source Software |

| DXF-Import | possible |

| Draw shapes in software | possible |

| Camera optics and magnification | included |

| 23" Monitor | included |

Further facts

| Radius dressing | possible |

| Dressing wheel packs | possible |

| Enclosure | included |

Technical data GWDress-500

General

| General Adapter/connectors | HSK 63 or customer-specific option |

| Max. grinding wheel diameter | ø 450 mm (expandable up to ø 650 mm) |

| Max. dressing wheel diameter | ø 250 mm |

| Grinding wheel speed |

0–1500 rpm (infinitely variable) |

| Dressing wheel speed | 0–2800 rpm (infinitely variable) |

Axis Travel Range

| Max. left/right travel | 200 mm |

| Max. forward/backward travel | 180 mm |

Dressing

| Oscillation movement | 0-50 rpm |

| Dressing wheel swing length | 0-90 mm |

| Optical scale system (X, Y, and rotary axis) | 0,001 mm |

Machine Data

| Electrical connection | 380 V or on request |

| Total power | 5 kW |

| Dimensions | approx. L 2337 x W 1380 x H 1900 mm |

| Weight incl. cast-steel machine bed | 2.900 kg |

Software

| GWDress Studio Software | Open Source Software |

| DXF-Import | possible |

| Drawing shapes in the software | possible |

| Camera optics and magnification | included |

| 23" monitor | included |

Additional Information

| Radius dressing | possible |

| Dressing of wheel sets | possible |

Downloads

More Impressions

We can show you what they can do!

Electrodes

Used machines